Day 2 :

Keynote Forum

Jon Binner

University of Birmingham, UK

Keynote: Development of high and ultra-high temperature ceramic matrix composites

Time : 09:30-10:10

Biography:

Jon Binner is the Deputy Head of the Engineering & Physical Sciences College, and Professor of Ceramic Science & Engineering in the School of Metallurgy and Materials, at the University of Birmingham. He has published about 220 research papers, as well as editing or contributing to 19 books, given around 60 keynote, plenary and invited talks at international conferences and holds 7 patents. He has won 128 research grants totalling about £16.3M, many have been international in nature. He is a Fellow of the American Ceramic Society (ACerS), the European Ceramic Society (ECerS), the Institute of Materials, Minerals & Mining (IOM3) and the Association for Microwave Power in Europe for Research and Education (Ampere). He was the President of the IOM3 from 2012-14 and is currently President-Elect of ECerS. The IOM3 awarded him the Holliday Prize in 1995, the Ivor Jenkins Medal in 2007 and the Verulam Medal & Prize in 2011.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

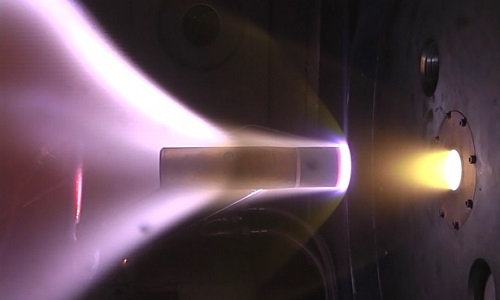

There is an increasing demand for advanced materials for aerospace and other applications, with temperature capability ranging from 1500℃ to well over 2000℃ and able to survive highly corrosive environments whilst subject to intense heat fluxes and mechanical stresses. The interaction of environmental conditions together with the requirement that dimensional stability is maintained makes the selection of suitable materials extremely challenging. This paper discusses the design, development, manufacture and testing of a new class of ceramic matrix composites based on either SiC or C fibre preforms and enriched with different ceramic powders as well as a matrix infiltrated by either microwave- or RF-heated chemical vapour infiltration (CVI). These composites will form suite of materials suitable for application in severe aerospace environments.

A Cfibre – HfB2 powder – Cmatrix composite being arc-jet tested at ~2700℃

Keynote Forum

Shouxun Ji

Brunel University London, UK

Keynote: The formation mechanism of metastable Al6(Fe, Mn) phase in die-cast Al-Mg alloys

Time : 10:10-10:50

Biography:

Shouxun Ji is currently a Lecturer at BCAST. Before rejoining Brunel in October 2010, he was a Manager at Arcadia, leading a team working on various projects to develop products and managing supply chains. Prior to that, he was the Chief Engineer of BCAST specialized in semi-solid processing of rheo-die casting, rheo-extrusion and rheo-twin roll casting. He is focusing on developing lightweight materials and structures for the automotive industry, including purpose developed aluminium and magnesium alloys with improved ductility, strength, modulus, or thermal conductivity, and the hybrid structures using different materials. He is also working on new materials for aerospace application, such as materials for explosive cords and high strength casting materials for aircraft. Meanwhile, he is in charge of all the equipment specification, planning and supply in the AMCC 1 and 2 programmes.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

The formation, 3D morphology and growth mechanism of Al6(Fe, Mn) phase were studied in Al-Mg-Mn-Fe alloys processed by high pressure die casting (HPDC). Thermodynamic calculation indicates that Al6(Fe, Mn) phase in the HPDC Al-Mg-Mn-Fe alloys is a metastable phase. The experimental results confirm that Mn addition in the alloy suppresses the transformation from metastable Al6(Fe, Mn) phase to stable Al13(Fe, Mn)4 phase under nonequilibrium solidification conditions. Energy-dispersive spectroscopy (EDS) analysis of extracted particles reveals that the average Mn/Fe atomic ratio in the Al6(Fe, Mn) phase decreases as the Mn/Fe atomic ratio in the melt decreases. It is also found that the Al6(Fe, Mn) phase grows to form two elongated prism morphologies: rhombic prism (equilibrium morphology, bounded by {110} and {002}), and rectangular prism (growth morphology, bounded by {002}, {200} and {020}). The primary Al6(Fe, Mn) phase shows hollow structure and the eutectic one is in the form of fine solid particles. The growth mechanism of Al6(Fe, Mn) phase is also elucidated according to the crystallographic rules and the morphological characteristics of Al6(Fe, Mn) phase.

(a) Crystal structure and 3D morphologies of Al6 (Fe, Mn) phase

- Materials Science and Chemistry | Materials Science and Engineering | Materials Chemistry in Developing Areas | Materials Synthesis and Characterization | Polymeric Materials

Location: Olimpica 2

Chair

Fargin Evelyne

ICMCB - Universite Bordeaux, France

Co-Chair

Xiaoying Li

University of Birmingham, UK

Session Introduction

Kyriakos Porfyrakis

University of Oxford, UK

Title: Orientation studies of endohedral nitrogen fullerenes and their watersolubilization, progress and opportunities

Time : 11:45-12:15

Biography:

Kyriakos Porfyrakis is an Associate Professor of Materials, an EPSRC Fellow and the Head of the Laboratory for Carbon Nanomaterials at the Department of Materials, University of Oxford. He has attracted over £2.5 M in funding as a Principal Investigator in the fields of Endohedral Fullerenes and Organic Electronics. He has over 100 publications (h-index: 27, i10-index: 52) that has attracted over 2370 citations. He has presented over 40 invited lectures and seminars, including 3 keynote lectures. In 2005, he won the Alan Glanvill Award of IOM3. In 2016, he was admitted as a Fellow at the Royal Society of Chemistry for his contributions to Chemical Sciences. He is the Academic Founder and Director of Designer Carbon Materials Ltd., a spinout company of the University of Oxford, aiming to commercialize endohedral fullerenes and their derivatives.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Paramagnetic endohedral fullerenes hold promise for a number of applications including quantum information processing and quantum sensing. In the case of endohedral nitrogen fullerenes such as N@C60 and N@C70, the nitrogen atom is almost completely isolated from the fullerene cage. This results in very long electron spin phase coherence times. The chemistry of endohedral nitrogen fullerenes has developed to a degree where it can be used to create functionalized systems with high aspect ratios that are prone to high alignment. This talk will deal with our recent results for several N@C60 and N@C70 derivatives aligned in liquid crystals. Within the liquid crystal matrix, we have achieved an order parameter factor Ozz of 0.61. This is a significant improvement on the best result that has been previously reported for endohedral fullerene derivatives. More importantly, this allows us to manipulate the intrinsic zero-field splitting (ZFS) of the spin resonance signal. By in situ rotating frozen endohedral fullerenes inside the magnetic field of the ESR spectrometer, we deliberately changed the orientation distribution of the molecules and tuned the splitting energy of ZFS. We achieved remarkable agreement between experimental values and simulation data. This work can be expanded to control of dipolar coupling for a two-qubit gate. Also, the water functionalization of N@C60 will be discussed. We have developed the first water-soluble derivative of N@C60 through the covalent attachment of a single addend, containing two permethylated β-cyclodextrin units to the surface of the carbon cage. The linewidth of the derivative's EPR signal is highly sensitive to both the nature of the solvent and the presence of Cu(II) ions in solution. Thus, we have shown that it has the potential to be used as a quantum sensor for other spin-active species.

Fargin Evelyne

ICMCB - Universite Bordeaux, France

Title: Surface engineering of soda lime silicate glass under thermal poling process for hardness reinforcement

Time : 12:15-12:45

Biography:

Fargin Evelyne has strong experience in nonlinear optical properties of glasses and particularly third and second order nonlinear susceptibility. She implanted in Bordeaux the surface glass processing by poling which is now developed with co-workers for composition, mechanical properties and optical structuring of the glass surface. She recently developed new heavy glass oxides for fiber applications thanks to strong collaborations inside an international laboratory LUMAQ (U. Bordeaux, COPL Laval, INRS Québec). She also was involved in the study and optimization of laser-induced defects in glasses and luminescence properties of flaws for the Megajoule Laser Facility in Bordeaux.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

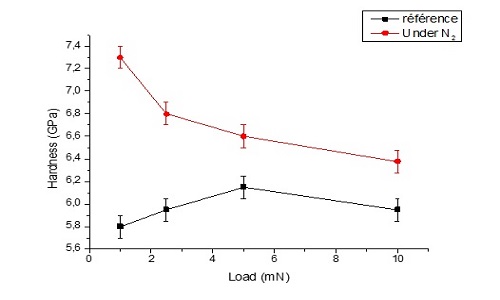

Surface engineering of soda-lime silicate glass has been performed by thermal poling and the correlation between the modification of the glass composition, the local structure and the mechanical properties of the field-induced modified surface has been investigated. Glow discharge optical emission spectroscopy (GD-OES) demonstrates the multi-layered structuring of the glass surface, due to the migration of mobile cations species. The nature of the atmosphere during poling directly impacts on the charge compensation mechanisms, the multi-layer shape and composition. This work demonstrates the presence of a pure layer of silica beneath the surface of the poled glass under N2 which strongly increases the mechanical properties of soda-lime glass, especially hardness. The thermal poling treatment is then used to enhance a densification of the poled region and a compressive stress at the silica nanometric layer surface.

Berkovitch nano-indentation results on unpoled reference versus poled soda-lime glass under N2

John O Roberts

University of Liverpool, UK

Title: Proposed link between the periodic table and the standard model

Time : 13:45-14:15

Biography:

John O Roberts has been an Open University Science Tutor for 30 years having attended Rutherford Appleton Lab and CERN as a summer school student. He has been a Freelance Tutor of Maths, Physics and Chemistry for many years and wrote the book “Those Infinities and the Periodic Table” over a period of 5 years from an idea in December 2010.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

The patterns of stable quantum states in the periodic table are inverted and extended to infinity in both directions to accommodate spatial variation relative to the nucleus. The upper end leads to a cut off point for white matter. The lower end represents quantum states in plasma. At 10-15 m to 10-20 m the interaction between weak, strong and gravity forces results in suitable boundary conditions for the production of elementary particles. Chemical classification of the elements requires convergence of chemical properties and quantum states. By defining group number as the maximum number of electrons in any one shell, hydrogen and helium are moved to the first set of 2(1)2 states first proposed by Janet. The atomic numbers are adjusted and mass number removed as it is an average of isotopes of each element produced in every supernova. This produces the Roberts Janet nuclear periodic table which proposes two zero states, a cut off and start point, of the electric field in attractive then repulsive modes. By symmetry of these fields energy states emerge in plasma with the counter intuitive property that the nearer the nucleus the greater the number of energy states. Fusion results and the consequential recycling implies a more rapid collapse than supernovae given sufficient energy density that could create an as yet unobserved interaction at 10-50 m to 10-65 m between the strong and gravity forces. String theory and extra dimensions may be required to explain such mechanisms and multiverses.

Jin An Wang

Instituto Politecnico Nacional, Mexico

Title: Correlation of oxygen defects with surface Lewis acidity and catalytic properties of hybrid MoO3/SBA-15 catalysts

Time : 14:15-14:45

Biography:

Jin An Wang is a full Professor in Chemical Engineering at the National Polytechnic Institute in Mexico City, Mexico. He is a National Researcher of Mexico and a Member of the Mexican Academy of Sciences. He is the Co-Author of more than 160 scientific publications, five patents, Co-Editor of three books in “Advanced Catalytic Materials” and three special volumes in Catalysis Today. He served as Chair of the first to fifth International Symposium on New Catalytic Materials. He was a Visiting Professor at Universidad Nacional Autónoma de Mexico, Universidad Autónoma Metropolitana and Worcester Polytechnic Institute in USA. His research interest focuses on the synthesis of new catalytic materials, catalysis for petroleum refining and treatment, catalysis for clean fuel production and environmental catalysis.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

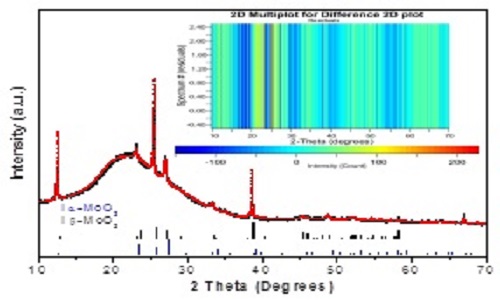

There are many structural defects or lattice vacancies in the surface of solid materials. From the surface sciences and catalysis points of view, these cationic or anionic defects are active centers for reactant adsorption and surface reactions. Investigation on structural defects and their correlation with reaction activity may provide new insight into the understanding of catalytic behaviors. In this work, a set of MoO3/SBA-15 mesoporous hybrid catalysts were characterized with a variety of spectroscopic techniques and their crystalline structures were refined with Rietveld method. Oxygen defect concentration, crystallite size, phase composition, surface acidity, mesoporous regularity and textural properties were reported. Both α‒MoO3 and β‒MoO3 phases coexisted but α‒MoO3 was predominated. Oxygen defects were created in the orthorhombic structure and its concentration decreased as MoO3 content increased. All the MoO3/SBA-15 catalysts chiefly contained a big number of Lewis acid sites originating from oxygen defects in MoO3 crystals. In the absence of formic acid, the oxidation of 4,6-dibenzothiophene in a model diesel was almost proportional to the number of Lewis acid sites of the catalysts. In the presence of formic acid, 4,6-dimethyldibenzothiophene (4,6‒DMDBT) oxidation was significantly affected by the formation of surface peroxometallic complex and Lewis acidity. Formic acid addition could improve the oxidative desulfurization (ODS) efficiency by promoting peroxometallic complex formation and enhancing oxidant stability. Under the optimal reaction condition using the best 15 and 20 wt% MoO3/SBA-15 catalysts, more than 99% 4,6‒DMDBT could be removed at 70°C within 30 min. This work confirmed that 4,6‒DMDBT oxidation is a texture and particle size sensitive and Lewis acidity dependent reaction. This work also shows that crystalline structure refinement combination with experiments can gain new insights in the design of heterogeneous nanocatalysts and help to better understand the catalytic behavior in the oxidative desulfurization reactions.

A Rietveld refinement plot for the 20 wt% MoO3/SBA-15 catalyst

Xiaoying Li

University of Birmingham, UK

Title: Ceramic conversion treatments of a low cost beta titanium alloy to combat wear

Time : 14:45-15:15

Biography:

Xiaoying Li received her PhD degree in Surface Engineering in 1999 and became a Senior Researcher in 2017 at the Surface Engineering Group, University of Birmingham, UK. As a Research Manager of the group, she has successfully completed a dozen of high quality research projects and published about 90 peer reviewed papers. She has delivered a dozen of invited talks to national and international conferences. Her research work has been focused on development of advanced surface engineering technologies, including novel ceramic conversion treatments of light alloys, low-temperature plasma surface alloying of stainless steels and recently surface modification of carbon fibres; microstructural characterisation of surface engineered materials, in particular the nature of metastable S-phase using cross-sectional TEM (XTEM) and more recently nano-surface fabrication and characterisation of nano composite materials using nanoindentation FIB/SEM and XTEM.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

The non-aerospace use of titanium alloys (such as in the motor sports industry) has become increasingly popular over the last 20 years due to their light weight, high ductility and high strength in conjunction with excellent corrosion resistance and outstanding biocompatibility. Titanium alloys are normally classified by their structure into the groups of alpha, alpha-beta and beta alloys. Advantages of beta alloys include excellent workability, good hardening properties, high corrosion resistance and excellent fatigue/crack propagation behavior. However, titanium and its alloys are characterized by inferior tribological properties including a high and unstable coefficient of friction and a strong scuffing tendency. Many surface engineering methods have been researched to combat the poor tribological properties of titanium and its alloys. Research carried out by Dong and Bell on the titanium alloy Ti-6Al-4V demonstrated the effectiveness of the thermal oxidation (TO) treatment in enhancing the wear resistance of the alpha/beta alloy. However, this process cannot be directly applied to the TIMET low cost beta (LCB) alloy since it is a metastable beta alloy. The long-time TO treatment at high-temperature will cause undue growth of the beta grains and excessive precipitation and growth of the alpha phase, thus leading to the degradation of the core mechanical properties of the beta-alloy. Therefore, the aim of this research was to enhance the tribological properties of TIMETAL LCB alloy without evoking a loss of core mechanical properties through developing new surface engineering processes based on integration of bulk heat treatment with surface ceramic conversion. The new integrated processes effectively harden the LCB without compromising the mechanical properties of the beta alloy. A dense adherent titanium oxide was formed on the oxygen hardened sublayer. The surface hardness was increased from 400 to 1100 HV and the sliding wear resistance was increased by more than 10 times following the optimal integrated treatment.

Akira Yamaguchi

Tokyo Institute of Technology, Japan

Title: Functionalization of MnO2 as a water oxidation catalysts in terms of the redox chemistry of Mn

Time : 15:15-15:45

Biography:

Akira Yamaguchi received his Doctor of Engineering degree at the University of Tokyo in 2015 for the work on functionalization of metal-oxide and sulfide minerals toward efficient multi-electron transfer catalysis with abundant elements under the direction of Prof. Kazuhito Hashimoto. After his Postdoctoral research in Dr. Ryuhei Nakamura’s laboratory of RIKEN from April 2015 to March 2016, he joined Tokyo Institute of Technology as an Assistant Professor. His particular field is Electrochemistry and his research interest includes the development of catalysts and the primordial carbon fixation on the Earth. Recently, he developed MnOx-based water oxidation catalysts inspired by the natural photosynthesis. Now he is aiming at the solar to chemical energy conversion system, called artificial photosynthesis, and his experience in developing water oxidation catalysts will contribute to this research fields.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

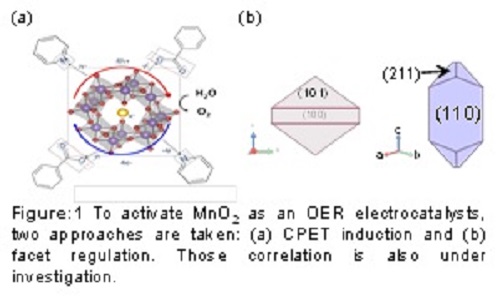

To overcome energy and environmental issues we are facing, fuel production from water and/or CO2 is highly demanding. Making fuels through both H+ and CO2 requires electrons, and the most abundant electron source in the world is water, like natural photosynthesis achieved by oxygen evolution reaction (OER: 2H2O → O2 + 4H+ + 4e-). Inspired by the oxygen evolution reaction (OER) center in natural photosynthesis, which is composed of CaMn4O5 cluster, numerous numbers of manganese oxide-based catalysts have been developed. However, their activity largely decreased under neutral pH. This work introduces the design strategy to enhance the OER activity of MnO2 electrocatalysts under neutral pH in terms of the redox chemistry of active Mn species. The key chemical species is Mn3+, which works as the intermediate of OER on MnO2 but unstable under neutral pH. To stabilize Mn3+, induction of concerted proton-electron transfer (CPET) and regulation of facet orientation were attempted. Regarding the CPET induction, introduction of pyridine into the electrolyte, which works as a CPET inducer, altered the reaction path and resulted in the activity enhancement. As to the facet orientation regulation, (101)-oriented MnO2 was synthesized based on the article which reports that Mn3+ is stabilized on (101) facet of rutile MnO2. The electrochemical OER examination revealed that (101)-oriented sample exhibited higher activity than (110)-oriented ones. The results indicate that those two approaches are efficient strategy to enhance the electrochemical OER activity of MnO2 under neutral pH. Further studies concerning the corporative effect of CPET and facet orientation have been under investigation.

Nana Gorgaslidze

Tbilisi State Medical University, Georgia

Title: Development of method for quantitative determination of bromelain in gel formulation

Time : 16:00-16:30

Biography:

Nana Gorgaslidze completed her PhD from Saint-Petersburg State Chemical-Pharmaceutical Academy, Russia. She is the Director of the Iovel Kutateladze Institute of Pharmacochemistry, Tbilisi State Medical University (TSMU) and Professor at the Department of Social and Clinical Pharmacy at TSMU. She has published more than 94 papers in reputed journals, authored four books and has two patents. She is a Member of organizing committee of several international conferences and meetings. She has more 40 years of teaching experience at the Tbilisi State Medical University, Georgia. She is the Founder of the Georgian Pharmaceutical Association (President: 2002–2005) and newspaper, Pharmacy. She is a Member of Scientist and Young Pharmacists of Georgia. She has long timework experience at the Ministry of Health, Labor and Social Affairs of Georgia in state control of quality medicinal and pharmaceutical products and other departments of the same minisity.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Gel of bromelain has anti-inflammatory properties and hence is used for treatment of edema and inflammations. This was developed at TSMU Iovel Kutateladze Institute of Pharmacochemistry. On previous researches we published the data of some properties of papain and bromelain containing gels. The presented work belongs to the development and validation of accurate and sensitive assay method for quantitative determination of bromelain in gel based on UV-spectrophotometric analysis. Elastasin was used as substrates for their analysis. Absorbance was recorded at 595 nm. The developed method is linear, precise and sensitive; Intra- and inter-day measurements. All methods were validated as per ICH guidelines and can be adopted for the routine analysis of bromelain in gel formulations.

Seda Cetintas

Kocaeli University, Turkey

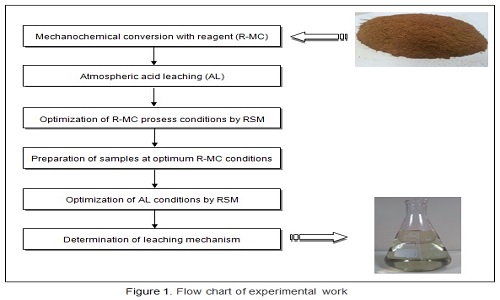

Title: YRF: A new hydrometallurgical process involving mechanochemical conversion with reagent

Time : 16:30-16:50

Biography:

Seda Cetintas graduated in 2011 from Department of Chemistry at Faculty of Science and Arts in Anadolu University. She received MD in 2014 and then started PhD in Chemistry from Kocaeli University. Her primary specialization was applications on recovery of metal values from ores and removal of impurities. Her secondary specialization was applications on statistical design of experiments. She is interested in applying these topics to several content areas in analytical chemistry, including separation, purification and enrichment. During PhD, she works in a research project on nickel recovery from lateritic ore.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

In this study, a new application of nickel improvement is proposed involving mechanochemical conversion with a reagent (R-MC) followed by an acid leaching (AL) process. It was developed based on the synergistic effects of high-energy milling and different chemical reagents which have a positive effect on extractive metallurgical leaching processes. The combination of R-MC as a pretreatment of AL aimed to overcome the disadvantages of traditional metallurgical processes used for nickel recovery, such as high temperature, high acid concentration, high cost and material requirements. For the statistical design of experiments combined with regression techniques, response surface methodology (RSM) involving central composite design (CCD) was applied to optimize the key factors that affect processes conditions in both R-MC and AL for high-efficiency nickel recovery. The optimum processes conditions of both R-MC and AL were determined for high-efficiency nickel recovery process by designing the experiment and performing a statistical analysis on the experimental data. The large determination coefficients (R2>95%) for each process indicated that CCD is a suitable design for both mechanochemical process with reagent and acid leaching. The FTIR, XRD and SEM analyses results support each other in that the application of mechanochemical processes has positive effects on valuable metal recovery in extractive metallurgy. In addition, the experimental data obtained from leaching experiments was evaluated according to shrinking core model equations to determine the advantages of mechanochemical processes on leaching kinetics. The leaching control step was identified as both chemically and diffusion-controlled by the shrinking core kinetic model. Thus, this study provided a new and more economical method in which mechanochemical pretreatments with reagents were combined with acid leaching. The positive effect of mechanochemical processes on leaching with reagents was defined by their high nickel efficiency (Ni(%)>95%) at lower acid concentrations (0.5 M

A Jedrzak

Poznan University of Technology, Poland

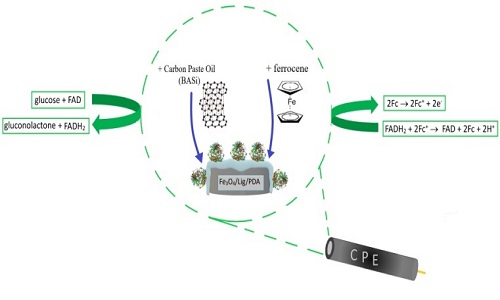

Title: YRF: Biosensor based on magnetite/lignin/polydopamine hybrid material combined with glucose oxidase for amperometric glucose biosensor

Time : 16:50-17:10

Biography:

A Jedrzak has received his MSc degree in Organic Chemistry in 2016 at Poznan University of Technology. Since 2016 he is a PhD student of Chemical Technology at Poznan University of Technology and also a Member of NanoBioMedical Centre in Poznan. His research interests are biosensors, enzymatic and catalytic systems and synthesis of hybrid/composite materials for nanomedicine.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

The development of technology has contributed to the intensification of research into the creation of more advanced materials. Such demands can be fulfilled by various inorganic-organic hybrid materials that were previously widely used in many fields in science also for enzyme immobilization or biosensors constructions. Rapid development of biosensor systems started after the first biosensor containing glucose oxidase was developed by Clark and Lyons in 1962. To this day, many scientists are working on new methods of creation to better detection, as evidenced by amounts of published papers. Novel innovative materials for glucose biosensor have gained enormous attention due to the need for a cheap and effective blood glucose monitoring. Monitoring of glucose level is important aspect in various media, like blood, fluids or juices. Despite the presence in the market of biochemical specialists for the qualitative and quantitative detection of glucose, the commercial available glucose monitoring device have become a crucial part of diabetes care or monosaccharide but has some limitations in accuracy and errors that can be limited due to manufacturing variances, storage, aging etc. Great efforts have been focused on the preparation of magnetite/lignin/polydopamine (Fe3O4/Lig/PDA) hybrid material combined with glucose oxidase for amperometric glucose biosensors. In this work a synthesis and physicochemical characterization of a novel magnetite/lignin/polydopamine (Fe3O4/Lig/PDA) material is presented as a novel and effective platform for enzyme immobilization and biosensing application. The platform has interesting features like improved thermal and mechanical stability, excellent adhesion for inorganic and organic materials, transferability of electrons and photo thermal properties. Greater material stability and durability and the extension of its attractiveness, compared to the current commercial products can be used in determining the level of glucose in different media like body fluids, juices, fruits.

Scheme presents construction of biosensor using a carbon paste electrode (CPE)

- Nanomaterials | Inorganic Materials Chemistry | Organic Materials Chemistry | Applied Materials Chemistry | Materials Chemistry and Physics | Science and Technology of Advanced Materials

Location: Olimpica 2

Chair

Alain Tressaud

ICMCB-CNRS-University of Bordeaux, France

Co-Chair

Lartigue Lenaic

Universite de Nantes, France

Session Introduction

Takeo Tomiyama

Hitachi Chemical Co., Ltd., Japan

Title: Optical anisotropy studies of silver nanowire/polymer composite films

Time : 11:05-11:35

Biography:

Takeo Tomiyama received his MS degree in Chemistry from Gakushuin University, Japan. He has been working at Hitachi Chemical Co., Ltd. His current research interests include the development and characterization of optical materials for information display applications.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Silver nanowire (AgNW) networks are one of the promising candidates as a next-generation transparent electrode material, given their high optical transparency and low electrical resistivity. AgNW networks based transparent conductive film can be fabricated by cost effective wet coating methods and exhibits better flexibility than the widely used indium tin oxide. The optical and electrical properties of AgNW networks have been extensively investigated in the past decade, both experimentally and theoretically. Previous researchers have discussed some aspects of optical properties such as transparency and haze, but have not presented a comprehensive study concerning optical constants (refractive index n and extinction coefficient k) of the AgNWs network. We have developed an AgNW/photosensitive polymer composite film that allows conductive patterning on a range of base materials. The composite films fabricated by roll-to-roll die coating exhibited optical and electrical anisotropy depending on the coating conditions. These problems motivated us to study the relation between the optical anisotropy, the electrical anisotropy and the orientation of AgNWs in the polymer matrix. To clarify the relation between the optical anisotropy, the electrical anisotropy and the orientation of AgNWs, the orthogonal optical constants of the composite films were determined by Mueller matrix spectroscopic ellipsometry. The orthogonal optical constants revealed the plasmonic natures of AgNW ensembles, and their anisotropy is correlated to the morphology of the composite film, where the long axis of AgNW is preferably oriented in the lengthwise film direction. We have demonstrated that the ellipsometric data analysis used in this study is effective to gain insight into the anisotropic optical properties of metal nanowires networks.

Alain Tressaud

ICMCB-CNRS, University Bordeaux, France

Title: Fluorine, a key-element for the XXIst century: Uses of fluoride materials in modern technologies

Time : 11:35-12:05

Biography:

Alain Tressaud is Emeritus Research Director at ICMCB-CNRS, Bordeaux University. He is the President of the European Academy of Sciences (Brussels) and member of several European Academies. He founded and chaired until 2008 the French CNRS Network on Fluorine Chemistry. Among the awards he received, the Atomic Centre Agency (CEA) Award of French Academy of Sciences (2008), ACS Fluorine Award (2011) and Moissan Prize (2013) can be quoted. His scientific interest covers synthetic fluorine chemistry, physical-chemical characterizations, applications in materials sciences, solid state chemistry. His works also deal with surface modification of materials and intercalation chemistry. His scientific production includes more than 360 papers in international journals, 20 chapters’ contributions in books and 12 internationalized patents. In addition, he edited 10 books, including the Editor-in-Chief responsibility of the book series “Advances in Fluorine Science” Elsevier (2006), “Progress in Fluorine Science”, Elsevier (2015), ”Progress in Science, Progress in Society”, Springer-Nature, (2017).

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Inorganic fluorine based compounds can be found as components in many applications, including energy storage and conversion, microphotonics, fluorescent chemical sensors, solid state lasers, nonlinear optics, nuclear cycle, superhydrophobic coatings, etc. Most of these outstanding properties can be correlated to the exceptional electronic properties of the fluorine element, yielding almost unique types of bonding with the other elements. The strategic importance of inorganic fluoride materials will be illustrated by several examples taken from various scientific domains: 1) In the field of energy storage, fluorinated carbon nano-particles (F-CNPs) have been tested as active materials in primary lithium batteries. In secondary Li batteries, 3d-transition metal fluorides and oxyfluorides mostly based on iron and titanium have been proposed as electrodes. 2) Nanocrystalline metal fluorides derived from fluorite (CaF2) or tysonite (LaF3) types exhibit high F- anionic conductivity that can be used as solid electrolytes in F- ion based all solid state batteries. 3) Upconversion and luminescent phenomena in nano fluorides based on rare earth metals. 4) Transparent fluoride ceramics which may challenge single crystals or glasses for solid state lasers applications. 5) Among transparent conductive oxides and oxide-fluorides, F-doped SnO2 exhibits rather good transparency in the visible range and high infrared absorption associated to its conductivity due to n-type charge carriers. 6) Perovskite related solid state fluorides based on d-transition metals exhibit a huge variety of structural and magnetic behaviors. Layered BaMF4 and iron fluorides (TTB- K3Fe5F15) are important families of multiferroics, in which magnetism and ferroelectricity coexist. 7) Intercalation of fluorine in several networks of oxides allows tuning the transition metal oxidation state. Superconductivity was created in F-doped cuprate systems La2CuO4 and Sr2CuO3 using low-temperature fluorination by F2 gas, or in F-doped oxypnictide LnFePnO1-xFx (Tc ~58 K). Finally, functionalization processes using various fluorination treatments yield nanosized materials, high surface area fluorides, or switchable hydrophobic/hydrophilic coatings.

The nanosize of F-CNPs obtained from nano-carbons prepared in molten carbonates (b), is not changed after low-temperature F2 fluorination (a)

Mitsuharu Tabuchi

National Institute of Advanced Industrial Science and Technology, Japan

Title: Synthesis of Co-free & Li-excess positive electrode materials for lithium-ion battery

Time : 12:05-12:35

Biography:

Mitsuharu Tabuchi is a solid-state Chemist, developing novel positive electrode materials for lithium-ion battery. He developed an original synthetic route to accomplish a complete mixing of two or three kinds of transition metal ions at AIST. He is also skilled in Rietveld x-ray analysis and 57Fe Mössbauer spectroscopy for material characterization.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

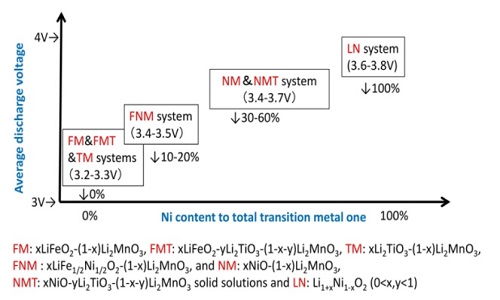

Abstract:

Co-free positive electrode material is necessary as constituent material for large-scale lithium-ion battery to use electronic vehicle (EV) and plug-in hybrid one (PHEV). As shown in Figure 1, we developed seven high-capacity material systems (>200 mAh/g) having above 3.2 V of discharge voltages. Our strategy was utilizing Fe ion for oxide-based positive electrode material, because iron is cheap and environmental-friendly element and LiFeO2 is as an electrochemically inactive positive electrode material. To activate the LiFeO2 component, we have been trying to make novel LiFeO2-Li2MnO3 solid solution (FM system). The first paper was published in 2001 and the study is still going on to improve its electrochemical property. To synthesize homogeneous FM sample with high Fe content, careful optimization of preparation condition must be needed. Original co-precipitation–calcination method was constructed. The co-precipitation temperature was kept to low temperature (-10ºC) to avoid spinel ferrite formation and then it wet-oxidized by bubbling with air. This precursor preparation technique is very important. After washing and mixing with Li salt, the mixture was dried for pulverization. It calcined in air or N2 flow. Other systems were derived from the FM one. Among them, the LiFe1/2Ni1/2O2-Li2MnO3 solid solution(FNM system) was designed to raise discharge voltage close to 3.5 V. Applying stepwise-charging method, its electrochemical properties was rather improved. LiFeO2-Li2MnO3-Li2TiO3 (FMT system) and Li2TiO3-Li2MnO3 (TM system) solid solutions were synthesized by co-precipitation–calcination-carbothermal reduction process. NiO-Li2MnO3 (NM system) and NiO-Li2MnO3-Li2TiO3 (NMT system) was prepared by co-precipitation–hydrothermal–calcination process. The LN system was considered as Li-excess LiNiO2 which was synthesized by thermal decomposition of Li2NiO3. Research details for these selected systems will be presented.

Our developed positive electrode materials vs. their average discharge voltages

Lartigue Lenaic

Universite de Nantes, France

Title: Ultra-bright magnetic nanoassemblies as theranostic agents

Time : 12:35-13:05

Biography:

Lartigue Lenaic has his expertise in size-controlled functionalized magnetic NPs or gold nanoshell and their incorporation in supramolecular fluorescent nano-assemblies. This multimodal nano-assembly was tested as (i) mediator for magnetic hyperthermia and photothermal; (ii) contrast agent for fluorescent imaging, MRI and photoacoustic; (iii) real-time monitoring and on-demand drug delivery system. He received his PhD in 2010 entitled: Synthesis, characterization, functionalization and biomedical applications of iron-based NPs, under the supervision of Dr. Y Guari and Pr. D Gatteschi. Then, he completed two years of Postdoctoral research in the group of Dr. F Gazeau where he studied the physical, magneto-thermal properties and the biotransformation phenomenon of iron oxide NPs. In 2012 he joined the team of Dr. D Alloyeau and synthesized, characterized and studied the biodegradation of iron oxide@gold nano-assemblies. Since September 2013, he was appointed Assistant Professor in the team of Pr. E Ishow. He has co-authored 29 scientific articles on peer reviewed international journals of Chemistry and Physics (h-index ISI Web of Science = 14) and he is currently involved in five research projects in the nanomedicine field including one as coordinator.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

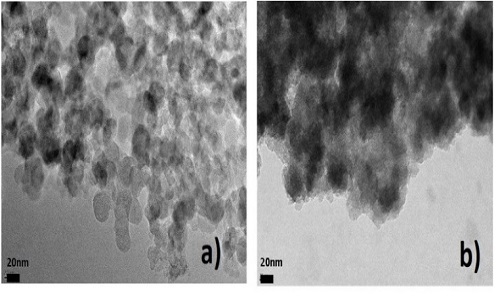

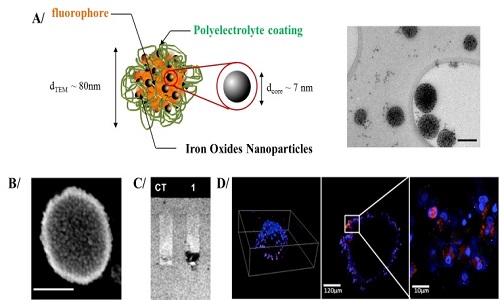

Multifunctional nanoparticles have recently emerged as promising cross-correlated contrast agents for bioimaging and carrier for drug delivery. The combination of magnetic and fluorescent units inside the same assemblies allows in vitro fluorescence microscopy (multiplexing, sensitivity and high resolution) and in vivo magnetic resonance imaging (MRI) (no penetration limit) with the same nanotools. We report a one-step synthesis to prepare core-shell architectures displaying a high payload of self-assembled magnetic and fluorescent units for improved multimodal tracking. This innovative architecture could contain drug agents for on-demand drug delivery. The multifunctional nanoparticles displayed a core-shell structure. The core consists an ultra-bright fluorescent organic nanoparticle (brightness>107 mol-1Lcm-1) tightly coated with superparamagnetic iron oxide nanoparticles, known as highly sensitive MRI contrast agents. The closely packed magnetic nanoparticles create strong additivity at the surface (r2=250 s-1mmol-1L), so that large MRI T2 contrast was obtained with unusually diluted solutions in vitro or after intravenous injection in small rodents. Two-photon excited fluorescence imaging could be performed, achieving unprecedented location resolution for agents combining both magnetic nanoparticles and fluorescence properties. Post-functionalization is ensured through an anionic polymer which is readily tailored to ensure furtivity (PEG chain) or active targeting (biotin, protein, etc.) via surface bioconjugation. In vitro studies show the importance of the polymer nature on the kinetics of cellular uptake. In vitro studies are performed on various cells and demonstrated the non-toxicity of our systems. Endocytosis kinetics was elucidated in mesothelium cancer cells grown as monolayers or multicellular tumor cell spheroids. Compared to numerous architectures like polymersomes or liposomes, the reported innovative nanoassemblies display in vitro a very high structural cohesion. The high density of magnetic nanoparticles leads to cooperative dipole effects, so that straightforward comparative investigations at various scales can be achieved using two-photon excited fluorescence imaging and in vivo magnetic resonance imaging (MRI).

Paolo Arosio

Universita degli Studi di Milano, Italy

Title: Magnetic nanoparticles: The effect of chemico-physical parameters on their fundamental and biomedical applicative properties

Time : 14:05-14:35

Biography:

Paolo Arosio is currently a fixed-term Researcher at Physics Department of Universita’ degli Studi di Milano. His main research activity regards the magnetism of nanoparticles and magnetic materials and the morpho-dimensional studies on biological samples in the AFM/NMR group of the Physics Department, that collaborates with numerous Italian and European research groups. Since 2011 he is responsible of NMR experimental activity of his research group.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

In the last two decades, much attention was devoted to novel multifunctional nanostructures based on magnetic nanoparticles (MNPs) useful as agents for magnetic resonance imaging (MRI), optical imaging and magnetic fluid hyperthermia, carriers for drugs and molecular targeting vectors. Most of the magnetic nanoparticles systems reported in literature by a lot of research groups have been shown to be useful as MRI contrast agents and magnetic fluid hyperthermia (MFH) mediators, displaying high nuclear relaxivity and specific absorption rate (SAR). For these compounds, the possibility to collect images of the regions where the MNPs are delivered through MRI and eventually optical imaging (if functionalized with a luminescent molecule), is joint to their use under radio-frequency fields, with frequency of the order of 100 KHz, which causes a local release of heat directed to tumour cells (the MFH effect), possibly inducing their death. By such materials, theranostic agents can be obtained. On the other hand, in the field of drug delivery and molecular targeting, few examples of reproducible experiments using superparamagnetic nanoparticles are actually present in literature. Thus, the application of MNPs to nanomedicine is currently of growing interest in the world. The main objectives of my research group in the last decade was to contribute to the knowledge of physical mechanisms at the basis of MNPs uses in biomedicine (especially MRI) and to propose some novel systems in strict collaboration with different research groups of chemists and biologists. I will present different novel systems able to contrast MRI images, act as good magnetic fluid hyperthermia agent or as multifunctional (magneto-fluorescent) agent and carry antitumoral drugs like e.g. paclitaxel or targeting functionalizations like PNA (peptide nucleic acids). Other examples of biomedical applications of MNPs magnetism will be also illustrated.

A magnetic nanoparticles and its crucial characteristics

Oluwatobi S Oluwafemi

University of Johannesburg, South Africa

Title: Simple green synthesis of amino acid functionalised CdTe/CdSe/ZnSe core-multi shell with improved cell viability for cellular imaging

Time : 14:35-15:05

Biography:

Oluwatobi S Oluwafemi is a National Research Foundation (NRF) South Africa rated Researcher at the Department of Applied Chemistry, University of Johannesburg. His research is in the broad area of nanotechnology and include green synthesis of semiconductor and metal nanomaterials for different applications which include but not limited to biological (imaging, labeling, therapeutic), optical, environmental and water treatment. He has author and co-author many journal publications, book chapter and books. He is a reviewer for many international journals in the field of nanotechnology and has won many accolades both local and international.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

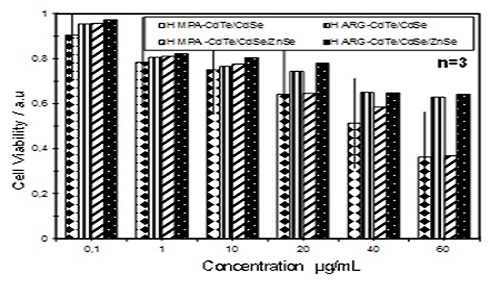

We herein report a simple, economical and green synthesis of highly fluorescent, water soluble and stable arginine functionalized CdTe/CdSe/ZnSe multi core-shell nanoparticles (NPs) with enhanced cell viability for cellular imaging. The synthesis of the CdTe/CdSe/ZnSe NPs was carried out under ambient conditions in the absence of an inert environment. The as-prepared NPs were characterized using UV-Vis absorption and photoluminescence (PL) spectroscopy, energy dispersive spectroscopy (EDS) and high resolution transmission electron microscopy (HRTEM). The optical analyses showed an enhancement in the fluorescent intensity after the functionalization with improved optical properties. The functionalized NPs (F-NPs) displayed higher cell viability compared to the bare NPs when investigated on KM-Luc/GFP cell line at different concentrations. The fluorescent image indicated that the as-synthesized functionalized NPs were taken up by the cells. Recommendations are made for treatment centers to become trauma- informed that would help this recognition.

Elif Cerrahoglu

Kocaeli University, Turkey

Title: YRF: Optimization of mechanochemical modification process of a lignocellulosic biomass waste for adsorption applications

Time : 15:05-15:25

Biography:

Elif Cerrahoglu completed her Under-graduation in the Chemistry Department at 2010, Biology Department at 2011 and MD in Enzyme Extraction, Immobilization and Purification topics in Biochemistry in Sakarya University, Turkey. She started her PhD in Analytical Chemistry while simultaneously working as a Research Assistant at 2014 in Kocaeli University, Turkey. Currently, she has been working on heavy metal adsorption, biomass waste materials, and waste material’s modification methods.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

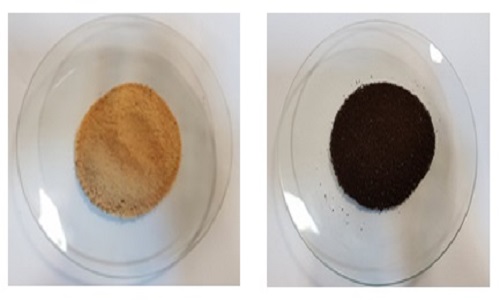

Most environmental pollutants have destructive effects on soil and water quality, plant and animal nutrition and human health. Especially metal pollution is a major health hazard that leads to environmental concern, and unlike organic pollutants, it is not biodegraded by natural means. The main reason for the accumulation of heavy metals, which are among the most important pollutants in the water are industrial wastes originating from facilities such as metal coating, battery production, fertilizer and paper industry, mining enterprises in developed countries in particular. Heavy metals such as lead, nickel, iron, zinc, manganese and cadmium are not biodegradable like organic species and at concentrations above certain limit values they are also found to play a major role in cognitive deficiencies, behavioral disorders, central nervous system, lungs and many vital organs causing injury. Therefore, the removal of these heavy metals is an important research topic especially for those working in the fields of analytical and environmental chemistry. The lignocellulosic wastes have adsorption potential due to the carboxylate, aromatic carboxylate, phenolic hydroxyl and oxyl groups present in the structures. However, the nature of the restricted adsorptive ability has to be increased by various physical or chemical processes. In this study, it has been aimed to use a lignocellulosic bio waste to remove heavy metals which are the most important pollutants in the water. For raw material with low uptake, activation is possible by means of environmental friendly, low-cost and high-performance mechanochemical modification methods with reagent, instead of existing activation methods. For mechanochemical modification with reagents, a planetary ball mill has been used. Parameters effective for mechanochemical modification such as milling time, rotation speed, raw material/reagent ratio and material/ball ratio have been optimized with response surface methodology (RSM), and the adsorption capacities of these new materials have been investigated for Cu(II), Pb(II), Zn(II) heavy metals.

- Poster Presentations

Location: Foyer

Chair

Lartigue Lenaic

Universite de Nantes, France

Session Introduction

Anatoly Bortun

PIDC, USA

Title: Mesoporous CeO2-ZrO2-based mixed oxides for automotive catalysis

Biography:

Anatoly Bortun has 20 years academy and 15 years industry experience with background in Physical and Inorganic Chemistry. His expertise is in areas of adsorption/ion exchange, separations and materials chemistry, including hydrothermal, sol-gel and solid state syntheses.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

New automotive emission standards make stringent requirements for oxygen-storage materials used in three way catalysts (TWC) and diesel catalysts. PIDC has developed an original precipitation technique for making wide range of ceria-zirconia (CZ) compositions. The key feature of the novel process is a presence of certain organic and/or inorganic additives specifically interacting with polyvalent metals in aqueous solution. The dual role of additives has been found. They change primary particles charge and surface charge density. Also, they specifically interact with Zr(Ce) species by occupying or blocking some of their active sites, which prevents dense packing of primary particles and their aggregates. This allows tailored assembly of mixed oxide structural blocks throughout all stages of precipitation with the formation of open-framework hierarchical structures. Other synthetic steps – washing precipitate from ionic admixtures, drying, calcinations, etc., are also important for retaining and fixation of hydrogel open-framework structures. Based on experimental data optimal conditions for making mixed oxides with porosity that can be controlled and regulated in a broad range from 50-10 nm up to 60-100 nm and improved thermal stability up to 1100oC have been determined. Novel CZ materials exhibit high oxygen storage capacity and improved compatibility with precious metals. Results of CZ characterization with the use of different methods: XRD, SEM, TEM, N2 adsorption, TPR-H2, etc., will be presented.

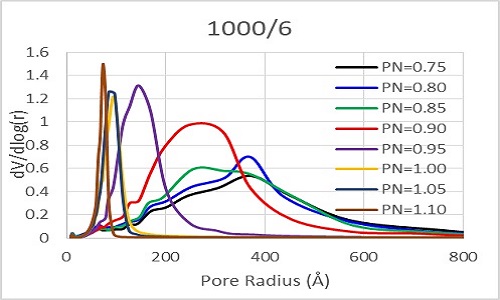

Pore size distribution of 70% ZrO2 - 20% CeO2 - 10% RE aged at 1000oC for 6 hrs as a function of the amount of complexing additive

Mihai I Sturza

IFW Dresden - Institute for Solid State Research, Germany

Title: Novel low dimensional mixed valent transition metal chalcogenides discovered by exploratory synthesis

Biography:

Mihai I Sturza has his expertise in synthesis and crystal structure characterization of novel inorganic compounds. The main aim of his work is to synthesize new inorganic compounds (new oxides, oxo-halides, pnictides, chalcogenides, intermetallics, etc.) and to correlate their chemical and physical properties to their compositions and crystal structures. His research at IFW involves searching for novel low-dimensional materials with interesting electronic properties emerging from a competition between different electronic states or a suppression of the electronic order (charge, orbital or spin).

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

The class of transition-metal chalcogenides that exhibits mixed valency has been of continuing interest for several decades. The emergence of superconductivity with a superconducting transition temperature (Tc<30 K) in mixed-valence AxFe2−ySe2 (A=K, Rb, Cs, and Tl) phases has further increased interest in the chemistry and physics of complex ternary transition-metal chalcogenides. Copper chalcogenide materials are of considerable scientific interest because of their rich structural and compositional diversity, mixed valency, propensity for phase transitions, charge-density waves, potential for ionic mobility, as well as applications such as high performance photovoltaic cells. New results from the chemistry of the A/Cu/Q (A=Na, K, Ba; Q=S, Se) system will be reported. The synthesis, crystal structure, and properties of new layered copper chalcogenide compounds, which are mixed-valent will be presented. Single crystals were grown by the reaction of Cu metal in a molten alkali/ alkaline-earth metal/polysulfide/polyselenide/flux. Single crystal x-ray diffraction measurements performed on several crystals showed a high quality of the crystals, proven by the good internal consistency of the data collected using the full-sphere mode and an extremely low R factor. Electronic band structure calculations and physical property measurements reveal p-type metallic behavior, with moderately high electrical conductivity and hole carrier mobilities.

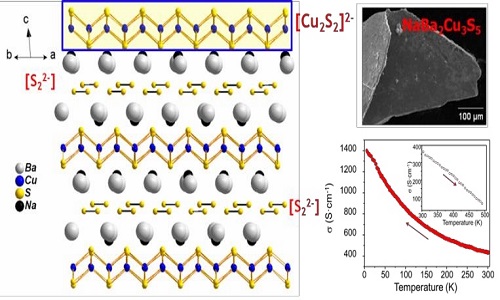

Crystal structure, SEM image and conductivity measurement of NaBa2Cu3S5 crystal, a novel mixed-valent transition metal chalcogenide discovered by polychalcogenide flux synthesis

Nana N Barbakadze

Tbilisi State Medical University, Georgia

Title: Synthesis of hydrazones of 5α-androstane series

Biography:

Nana N Barbakadze has completed her PhD from Ivane Javakhishvili Tbilisi State University. She is a Research Scientist at Tbilisi State Medical University. Her field of interest is in chemistry and synthesis of biologically active compounds. She is the Author of more than 15 papers in reputed journals and has presented her work at 40 international scientific conferences.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Recently, steroidal hydrazones have been receiving extensive attention of scientists because they have shown to exhibit antibacterial, antiviral and anticancer activities. Previously synthesized by us, some 5α-steroidal hydrazones have shown high antitubercular and antiviral activities. In order to find new potential bioactive compounds, hydrazones of 5α-androstane series have been synthesized. The starting ketones, 3α-hydroxy-5α-androst-9(11)-en-17-one and 5α-androst-2-en-17-one have been obtained by multistep modification of epiandrosterone — intermediate product of transformation of tigogenin. The structures of new hydrazones have been established by IR-, NMR- and mass spectral data.

Nana N Barbakadze

Tbilisi State Medical University, Georgia

Title: Synthesis of derivatives of adamantane modified epiandrosterone

Biography:

Nana N Barbakadze has completed her PhD from Ivane Javakhishvili Tbilisi State University. She is a Research Scientist at Tbilisi State Medical University. Her field of interest lies in chemistry and synthesis of biologically active compounds. She is the author of more than 15 papers in reputed journals and presentations at 40 international scientific conferences.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Esterified steroids are characterized with high biological activities. It is ascertained that inclusion of adamantane fragment into the steroidal compound improves its lipophilicity and the ability to permeate a cell membrane, which in and of itself results in increased biological activity. Inclusion of the radical of adamantane into the molecule of a substance often tends to decrease the toxicity of this compound, while also prolonging the ability of this compound to be biologically active. In order to study relationship of structure-activity by esterification of epiandrosterone with chloranhydride of adamantane acid 3β–(1–adamantoat)–5α-androstan-17-one has been synthesized. By its interaction with hydroxylamine, semicarbazide and hydrazines (phenylhydrazine, p-methyl-, p-bromo-, p-chloro-, p-phenyl-, p-nitro-, 2,4-dinitrophenylhydrazines) corresponding oxime and hydrazones have been obtained. Starting epiandrosterone was synthesized by conversation of 3β-acetoxy-5α-pregn-16-en-3β-ol-20-one – splitting product of tigogenine.

Florina Teodorescu

Center for Organic Chemistry - Romanian Academy, Romania

Title: Catalytic synthesis of alkylpyrazines over mixed oxides obtained from LDHs materials

Biography:

Florina Teodorescu, a Senior Researcher, has her expertise in novel organic synthesis and catalyze. Her capabilities include techniques and methods required for materials synthesis and characterization and analytical skills necessary for characterization of organic compounds.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

In our study, mixed oxides obtained from layered double hydroxides (LDHs) were evaluated as catalysts in pyrazines synthesis by cyclization of different 1,2 diamines with propylene glycol. For this purpose, the LDHs materials with a [M2+1-xM3+x(OH)2]x+[An-x/n]∙mH2O general formula, where M2+=Ni, Zn, Cu and M3+=Cr, Fe, Co, were obtained by two methods: co-precipitation and mechanochemical route. The LDH with a M2+/M3+ molar ratio of 3 was prepared at pH=10 by co-precipitation of two solutions: A (nitrates solutions) and B (alkaline solution) under low supersaturation. Both solutions were added simultaneously at a feed flow of 60 mL∙h-1 and mixed at room temperature under vigorous stirring in a batch reactor. The gel obtained was aged 18 h at 75°C, cooled to room temperature, filtered and washed with bi-distilled water until a neutral pH (7) of the washing water was reached. The drying of the hydrotalcite gel was performed at 90°C for 24 h in air flow. In the mechanochemical route, the required amounts of nitrates, Na2CO3 and NaOH were directly milled in a mortar for 1 h. The resulted white paste was then washed with bi-distilled water until pH of 7, and dried at 90°C for 24 h. Dried samples were subsequently calcined at 450°C in order to achieve the mixed oxides. The catalytic activity measurements were carried out at atmosphere pressure in a fixed-bed down-flow integral reactor at 300-400°C. There is a significant influence in the conversion and selectivity values offered by the type of cation used, the method of preparation of LDH precursors, the temperature, space velocity and the molar ratio of the reactants. The Lewis acid sites play an important role in activity values of catalytic materials.

Jeong-Hoon Kim

KRICT - Carbon Resources Institute, South Korea

Title: Separation of by-product gases in steel industry for carbon resources utilization by semialicyclic polyimide membranes

Biography:

Jeong Hoon Kim is Head of Greenhouse Gas Separation and Recovery Research Group, Carbon Resources Institute, KRICT. He got his BS and MS degree at Hanyang University in 1984 and 1986, respectively, and got his PhD from Korea Advanced Institute of Technology (KAIST) in 1999. He also worked as a Postdoc position at the Department of Chemical Engineering in University of Waterloo, Canada in 2000-2001. He has intensively been studying the synthesis of polymer membranes, fabrication of asymmetric flat and hollow fiber membranes, and development of multi-stage membrane process in the field of gas separation, electrodialysis, pervaporation, water purification, electrodialysis, and fuel cells since 1984. He published about 65 papers in Korean Journals and 30 papers in international Journals, and owns more than 100 Korean and international patents.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

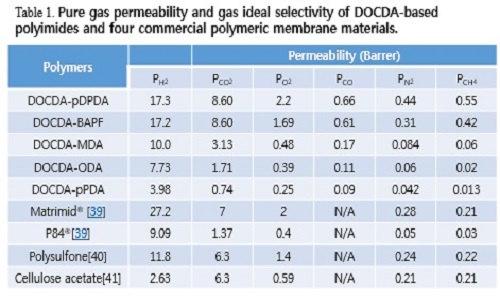

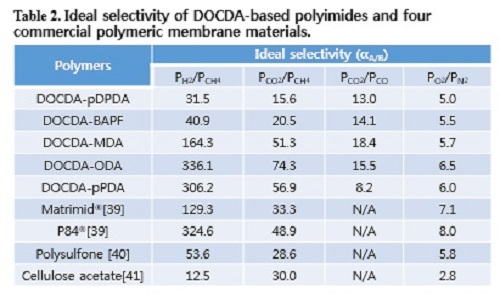

Huge amount of by-product gas mixtures (H2, CH4, CO, CO2, N2, etc.) has been produced from steel industry in Korea and worldwide. Among the by-product gases, CH4 and H2 are included in coke oven gas (COG). CO2 and CO is included in blast furnace gas (BFG) and Linz Donawitz gas (LDG) in steel industry. If they can be efficiently separated at high purity and recovery, they can be used valuably for carbon capture and utilization (CCU) producing chemical products such as methanol, ethanol, ethylene, acetic acid, etc. and therefore, contributing to reduction of global warming. There are typical separation technologies: cryogenic, adsorption, absorption and membrane. Membrane technology can be a promising new separation technology owing to cheap plant construction, easy operation, environmental friendliness etc. The economy and energy efficiency of membrane process depends mainly upon gas selectivity and gas permeability of membrane materials. This study shows the preliminary result for the gas separation properties of soluble polyimides as membrane materials - CO2/N2 (or CO2/CO) and H2/CH4 (or CO2/CH4) selectivities and CO2 and H2 permeabilities. We have developed an alicyclic dianhydride-5-(2,5-dioxotetrahydrofuryl)-3-methyl-3-cyclohexene-1,2 dicarboxylic anhydride (DOCDA) based homo- and co-polyimides with various dianhydrides and diamines using m-cresol as a solvent, respectively. Thin dense membranes were prepared from the copolyimides to check their gas permeation properties with a time-lag apparatus. All homo- and copolyimides showed good solubility for organic solvents and excellent thermal stability. The synthesized polyimides showed excellent CO2/N2 (or CO2/CO) and H2/CH4 (or CO2/CH4) selectivities, and high CO2 and H2 permeabilities. These results confirmed these polyimides could be used as membrane materials for the separation of CO2, CH4, H2 and from by-product gases in steel industry.

Nanuli Nadaraia

Tbilisi State Medical University, Georgia

Title: Synthesis of 5α-steroidal[17,16-d]pyrazolines

Biography:

Nanuli Nadaraia has completed her PhD from Mendeleev Moscow Chemical Technological Institute. She is a lead Research Scientist at Tbilisi State Medical University. Her field of interest is chemistry and synthesis of biologically active compounds. She is the author of more than 40 papers in reputed journals and presentations at 50 international scientific conferences.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Among the synthetic biologically active steroids pyrazolines have important place. Interest toward of these compounds is determined by their theoretical and practical meaning. Many steroidal pyrazolines have showed high anti-inflammatory, antitumor, antimicrobial and antiandrogen activities. 3β-Hydroxy-5α-pregn-16-en-20-one and its modified product - 3α-hydroxy-5α-pregna-9(11),16-dien-20-one have been synthesized from aglicon - tigogenin, isolated from plant Yucca gloriosa L. introduced in Georgia. By acid-catalyzed condensation of this α-enones with several hydrazines (phenyl-, p-chloro-, p-bromo-, p-methyl- and p-phenylphenylhydrazine) cyclocondensation products - 3β-hydroxy-1¢-aryl-3¢-methyl-5α-androstano[17,16-d]pyrazolines and 3α-hydroxy-1¢-aryl-3¢-methyl-5α-androst-9(11)-eno[17,16-d]pyrazolines have been synthesized and their biological activities have been studied.

Taiebeh Tamoradi

University of Kurdistan, Iran

Title: Synthesis of a new Cd-complex supported on magnetic nanoparticles and study of its catalytic activity for oxidation reactions

Biography:

Taiebeh Tamoradi obtained her Master’s in Inorganic Chemistry from Ilam University in 2012. In 2014, she joined Kurdistan University as a PhD candidate. After a two-year Postdoctoral Research position in Kurdistan University, she moved to the University of Ilam to join the Chemistry Science Group under Professor Arash Ghorbani Choghamarani.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

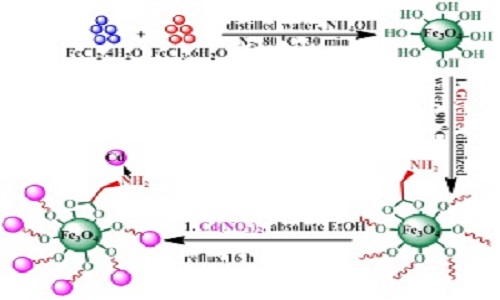

The simplified recovery, reusability and the potential for incorporation in continuous reactors and microreactors are unique properties in organic synthesis, thus the major area of research is recently shifted toward more environment friendly catalysts. In homogeneous systems it is complicated to recover the catalyst from the final reaction mixture; thus heterogeneous catalysts are used as supports. Heterogeneous catalysts have attracted a considerable attention in synthesis of organic compounds, because of their recovery by conventional filtration or centrifugation techniques. However, recovery and recycling of the heterogeneous catalysts are difficult because they require a tedious workup via filtration and the inevitable loss of solid in the recovery process. Magnetic nanoparticles have recently proposed as ideal supports because of their multifunctional physical and chemical properties such as easy preparation and functionalization, high chemical activity, long catalytic life, large surface area ratio, excellent thermal and chemical stability, low price, less toxicity, high dispersion and easy separation via external magnet. Sulfoxides, disulfides and sulfides are useful in the chemical industries and play a vital role in some medicines and biological processes. During the recent increasing interest in synthesis of these compounds, variety of catalysts has been received considerable attention. The present work describes the synthesis of a new cadmium complex immobilized on Fe3O4 nanostructure as efficient catalyst for oxidation reactions. Characterization of the prepared nanostructure was performed by SEM and XRD. Use of green medium, easy separation, excellent reusability of the nanocatalyst, and short reaction time are outstanding advantages of this method.

General route for the fabrication of Fe3O4-Glycine-Cd

Nana Gorgaslidze

Tbilisi State Medical University, Georgia

Title: Steroidal oximes modified by N-protected amino acids

Biography:

Nana Gorgaslidze completed her PhD from Saint-Petersburg State Chemical Pharmaceutical Academy, Russia. She is the Director of the Iovel Kutateladze Institute of Pharmacochemistry, Tbilisi State Medical University (TSMU) and Professor at the Department of Social and Clinical Pharmacy at TSMU. She has published more than 94 papers in reputed journals, authored four books and has two patents. She is a Member of organizing committee of several international conferences and meetings. She has more 40 years of teaching experience at the Tbilisi State Medical University, Georgia. She is the Founder of the Georgian Pharmaceutical Association (President: 2002–2005) and newspaper, Pharmacy. She is a Member of Scientist and Young Pharmacists of Georgia. She has long timework experience at the Ministry of Health, Labor and Social Affairs of Georgia state control of quality medicinal and pharmaceutical products and other departments of the same ministry.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Modification of steroids with pharmacophores in order to discover new highly active compounds is a critical problem. Peptides and proteins play an important role in biological and physiological processes and combinations of amino acids, peptides and steroids have given rise to an interesting class of biologically relevant compounds. Oximes have been evaluated for potential cytotoxicity and oxime derivatives of steroids that have been reported to exhibit antibacterial, anti-inflammatory and anti-cancer activities. In particular, amino acids have been coupled with steroids with the aim of preparing potential therapeutic agents that exhibit lower toxicity whilst retaining the original activity of the parent compound. In the pharmacological perspective, the combination of two important systems in one molecule encourages increasing the biological activity; accordingly the synthesis of steroidal peptides becomes interesting. The derivatives of different oximes modified by amino acids are noteworthy. Despite steroidal oximes being biologically highly active compounds, examples of modification similar to these compounds cannot be found in the literature. In order to synthesize biologically active compounds, O-acylation of 20-hydroximino-5α-pregn-16-en-3β-ole, 3β-acetoxy-20-hydroximino-5α-pregn-16-ene and 17-hydroximino-5α-androstan-3β-ole with N-protected amino acids (N-Cbz-L-Ala-Bt, N-Cbz-L-Val-Bt, N-Cbz-L-Phe-Bt and N-Cbz-L-Ala-L-Val-Bt) have been carried out and their antiviral activities have been studied.

Nana Gorgaslidze

Tbilisi State Medical University, Georgia

Title: The lipid composition of some plants growing in Georgia

Biography:

Nana Gorgaslidze completed her PhD from Saint-Petersburg State Chemical Pharmaceutical Academy, Russia. She is the Director of the Iovel Kutateladze Institute of Pharmacochemistry, Tbilisi State Medical University (TSMU) and Professor at the Department of Social and Clinical Pharmacy at TSMU. She has published more than 94 papers in reputed journals, authored four books and has two patents. She is a Member of organizing committee of several international conferences and meetings. She has more 40 years of teaching experience at the Tbilisi State Medical University, Georgia. She is the Founder of the Georgian Pharmaceutical Association (President: 2002–2005) and newspaper, Pharmacy. She is a Member of Scientist and Young Pharmacists of Georgia. She has long timework experience at the Ministry of Health, Labor and Social Affairs of Georgia state control of quality medicinal and pharmaceutical products and other departments of the same ministry.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

The aim of this work was to study the lipid composition of the fruit of Corylus avellana L. (Betulaceae) and seeds of Persica vulgaris L. (Rosaceae). Using the method of high performance liquid chromatography (HPLC), seven saturated, one mono-unsaturated and two poly-unsaturated fatty acids were identified. It is remarkable that hexadecanoic, 9-octadecenoic acid and 9, 12-octadecadienoic acids are predominant in fatty oil. From the fruits of Corylus avellana neutral lipids with a yield of 61%, relative to the air-dry raw material were obtained. Five phospholipids and seven amino acids were identified from the polar lipids of Corylus avellana. Fatty oils from the seeds of Persica vulgaris (Rosaceae) were studied. HPLC analysis of the fatty oils show presence of five saturated, one unsaturated and two poly-unsaturated fatty acids. Among of them dominants are: 9-octadecenoic acid, 9, 12-octadecadienoic and 9,12,15-octadecatrienoic acid, which are not synthesized in the human body and are presented as an irreplaceable fatty acids. The characteristics of the fatty acid composition of the fatty oil of the seeds of Persica vulgaris is related to the climatic conditions of the eastern regions of Georgia and corresponds to the tendency of growth of unsaturation with changing environmental factors.

Sungsoo Kim

Pai Chai University, Korea

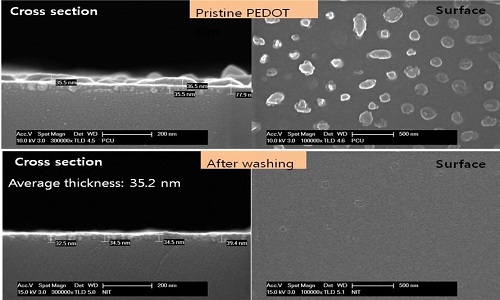

Title: Synthesis and characterization of ultra-thin and ultra-highly conductive poly(3,4- ethylenedioxythiophene) nanofilm

Biography:

Sungsoo Kim has his expertise in surface and colloid science as well as in materials science especially including conducting polymers and organic semiconductors. He has a broad and intensive experience in R&D in addition to accomplishments in supervision of many graduate students. He is currently working on several projects for an organic electrochemical transistor based on a functionalized PEDOT active layer.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Poly-3,4-ethylenedioxythiophene (PEDOT) is a very versatile and highly conductive polymer reported up to ca. 4,500 S/cm so far. In this study, PEDOT with an ultra-high conductivity of about 6,000 S/cm and an ultra-thin film of about 35 nm is presented. The PEDOT was processed via an oxidative chemical vapor phase polymerization method (VPP). Glass and PET surfaces were covered with ferric chloride (FeCl3) oxidizing agent mixed with polyurethane diol (DUDO) and poly(ethylene glycol–propylene glycol–ethylene glycol) (PEG-PPG-PEG) prior to their exposure to 3,4-ethylenedioxythiophene (EDOT) vapors. Optical microscope images show that the precursor film (oxidant mixture) covered on wafer or PET has very smooth and uniform surface. FE-SEM and AFM results revealed that PEDOT film after washing with n-butanol is very smooth, thin, and homogeneous (RMS is lower than 3 nm). Ultra-thin PEDOT films were further characterized by various other tools such as XRD, FT-IR, Raman, XPS, TGA, and so on. All other results obtained by various analyzing tools strongly support that PEDOT is indeed an ultra-highly conductive film far surpassing the most representative transparent electrode such as ITO (indium tin oxide).

Biography:

Zolaikha Rasouli has obtained her Masters’ degree in Science from Kurdistan University, UK in 2009. She was a PhD candidate in Analytical Chemistry, Kurdistan University, 2011. Her working field is focused on chemometrics modern methods at PhD level. She is currently working on a PhD thesis.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

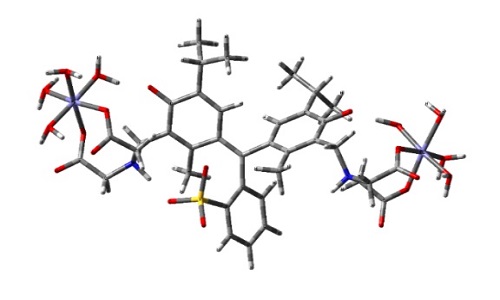

Over the past few years quantitative determinations of micro/macro minerals have attracted considerable attention. This attention is because of the essential role of minerals in various procedures i.e., medical, food, industrial and their numerous biological activities on human health. Chelation of chromomeric agents to metallic ions is one of the most efficient practices used in quantitative determination of micro/macro minerals in recent year. Herein, complexation systems formed by methylthymol blue (MTB) and ZnII, CuII and FeII metal ions in an aqueous solution with pH=5.0 have been described from experimental and theoretical points of view. It was characterized using UV-Vis absorption spectroscopy combined with soft/hard chemometrics methods and time dependent density functional theory (DFT/TD-DFT) calculations. First, an exploratory analysis from the acid-base system of MTB and each of the complex formation systems was carried out by Marquardt-Levenberg, MCR-ALS and RAFA algorithms. The results revealed that ZnII and CuII have the same behavior in confronting with MTB, both 1:2 and 1:1 stoichiometries of ZnII or CuII to MTB. However, for FeII, simultaneous formation of FeL and Fe2L complexes were suggested. In the second step of our work, we were interested to the description in detail of these systems by DFT/TD-DFT calculations to identify the nature of their structural geometries in the aqueous solution. For this purpose, we proposed the molecular hypothetical structures for different complex species based on the favorably moieties included in the complexation reactions, the protonation state of different functional groups of MTB and finally, the metal ion surrounding.

Molecular structure of Fe2L complex

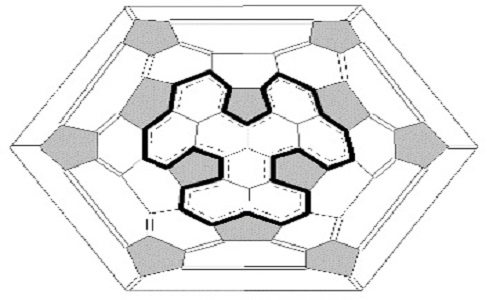

Ayrat R Khamatgalimov

Arbuzov Institute of Organic and Physical Chemistry - FRC Kazan Scientific Center of RAS, Russia

Title: Phenalenyl like substructures in fullerene molecules

Biography: