Biography

Biography: Anatoly Bortun

Abstract

New automotive emission standards make stringent requirements for oxygen-storage materials used in three way catalysts (TWC) and diesel catalysts. PIDC has developed an original precipitation technique for making wide range of ceria-zirconia (CZ) compositions. The key feature of the novel process is a presence of certain organic and/or inorganic additives specifically interacting with polyvalent metals in aqueous solution. The dual role of additives has been found. They change primary particles charge and surface charge density. Also, they specifically interact with Zr(Ce) species by occupying or blocking some of their active sites, which prevents dense packing of primary particles and their aggregates. This allows tailored assembly of mixed oxide structural blocks throughout all stages of precipitation with the formation of open-framework hierarchical structures. Other synthetic steps – washing precipitate from ionic admixtures, drying, calcinations, etc., are also important for retaining and fixation of hydrogel open-framework structures. Based on experimental data optimal conditions for making mixed oxides with porosity that can be controlled and regulated in a broad range from 50-10 nm up to 60-100 nm and improved thermal stability up to 1100oC have been determined. Novel CZ materials exhibit high oxygen storage capacity and improved compatibility with precious metals. Results of CZ characterization with the use of different methods: XRD, SEM, TEM, N2 adsorption, TPR-H2, etc., will be presented.

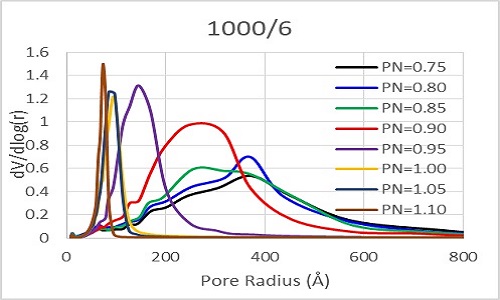

Pore size distribution of 70% ZrO2 - 20% CeO2 - 10% RE aged at 1000oC for 6 hrs as a function of the amount of complexing additive