Day 2 :

Keynote Forum

Jean Francois Silvain

ICMCB-CNRS, France

Keynote: Physical properties of metal-matrix composite materials

Time : 10:00-10:35

Biography:

Jean-Francois Silvain is a Senior Researcher at ICMCB-CNRS and an Adjunct Professor of Engineering at UNL-Lincoln, USA. He has obtained his Bachelor’s degree at Poitiers University in 1980 and PhD degree at Poitiers University in 1984, both in Material Science. He was a CNRS Research Fellow at the University of Nancy, France from 1987 to 2002. He has joined the ICMCB-CNRS in 1992. He has over 30 years of experience in composite materials processing and characterization at micro/nano scales. His main field of interest is the processing and the characterization of ceramic and inorganic multi materials ranging from metal matrix composite to functionally graded materials with the aim to develop materials with adaptive physical and/or mechanical properties.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Both high thermal conductivities and low thermal expansion coefficients (CTE) are required for heat-sink materials as they promote rapid heat dissipation and tolerate thermo-mechanical strains upon thermal cycling. Currently, Cu or Al heat sinks are being used. However, they are not suitable due to the large CTE mismatch with the ceramic and silicon parts in the components. To overcome this issue, we proposed to replace the Cu and Al heat sinks by metal matrix composites (MMCs), more particularly Al and Cu matrix composites reinforced with carbon. The properties in MMCs is often compromised by the absence of effective interfaces, especially in non-reactive systems such as Al(Al2O3)/C and Cu/C. However, for a thermally efficient assembly, the interface should allow proper transfer of thermo-mechanical loads between the materials, which is only possible in the presence of chemical bonding. Ex-situ and in-situ methods can be used to form interfacial metal-matrix zones with optimized physical properties. An ex-situ method developed in this study is correlated with the synthesis of a hybrid TiOx/TiC coating on carbon fibers (CFs) using molten salt synthesis. The molten salt synthesis method is a facile and efficient way for the synthesis of transition metal carbides at low temperatures in a relatively short time. The in-situ method is linked with the synthesis of composite materials by alloying the matrix with carbide forming elements which has been investigated using a well-known process used for Al-based composites. The solid-liquid coexistence allows the formation of a liquid phase which enhances the reactivity between the carbide forming element and the carbon reinforcement. For both ex-situ and in-situ MMC composite materials, the fabrication conditions will be correlated with the microstructures of the interfacial zones and the physical properties of the MMC materials.

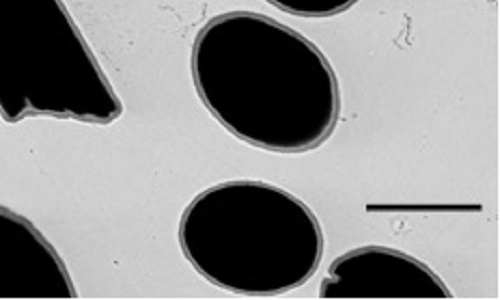

In situ formation of TiC interfacial zone between carbon fibers and copper matrix (bar equal 10 microns).

- Nanomaterials | Inorganic Materials Chemistry | Organic Materials Chemistry | Materials Chemistry and Physics | Science and Technology of Advanced Materials

Location: St. Gallen II

Chair

Jean-Francois Silvain

ICMCB-CNRS, France

Session Introduction

Tofik M Nagiev

Nagiev Institute of Catalysis and Inorganic Chemistry, Azerbaijan

Title: Nitrogen fixation at conjugated oxidation by hydrogen peroxide

Time : 12:05-12:25

Biography:

Tofik M Nagiev is a Vice-president of Azerbaijan National Academy of Sciences, Director of Research Center of “Azerbaijan National Encyclopedia” and Department chief of Nagiev Institute of Catalysis and inorganic chemistry of ANAS. He is the Professor of the department of the Physical and Colloid Chemistry of Baku State University.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

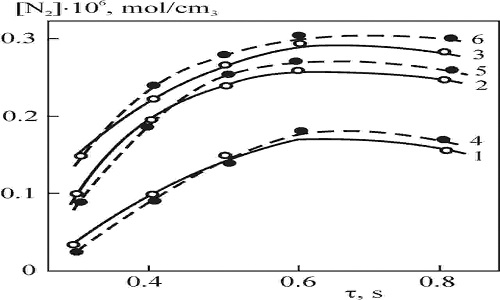

The problem of nitrogen fixation is one of the most important scientific and technical tasks. Nitrogen and nitrogen compound making industry is one of the leading branches of the modern chemical industry. The state of the art of it is the main factor affecting supply of nitrogenous fertilizers to agriculture and of various nitrogen-containing substances to industry. Fig 1 shows dependence of molecular nitrogen conversion on its volume rate in the temperature range of 773-873 K. It is clearly observed that the quantity of fixed nitrogen per injected molecular nitrogen increases to some extent with the amount of injected molecular nitrogen. A further increase of raw material rate does not change the level of nitrogen fixation. Despite shorter contact time, the increase of N2 volume rate from 1 to 4 l/h intensifies the reaction. The aqueous hydroperoxide rate is constant for all nitrogen rates. However, at nitrogen rate of 4-5 l/h the fixed nitrogen yield is altered. Thus, chemical induction is the main factor promoting N2 fixation in N2-H2O2-H2O system. It manifests itself owing to coupling of H2O2 dissociation reactions, which generate the intermediate-HO2 radical-to the system. This intermediate transfers the induction action of the primary reaction to N2 oxidation process. In this case, H2O2 is injected in amounts much greater than demanded by N2 oxidation, because the main requirement for effective chemical coupling is the presence of HO2 in high concentration. To conclude the discussion, it should be noted that oxidative fixation of molecular nitrogen with hydrogen peroxide is rather simple for process engineering design, usually proceeds under homogeneous conditions without any catalyst under atmospheric pressure, and produces high yield of fixed nitrogen.

Kinetics of nitrogen fixation with hydrogen peroxide: molar ratio N2:30% H2O2 = 1:1.6; 1 – 3 – T = 773, 823 and 873 K, respectively; 4 – 6 – theoretical curves at these temperatures

Alejandro Perez Florez

Pontificia Universidad Javeriana, Colombia

Title: A novel and facile route for CuMn-MgAl mixed oxides catalysts to catalytic degradation of violet crystal in water

Time : 12:25-12:45

Biography:

Alejandro Perez is currently working at the Pontificia Universidad Javeriana in Bogota, Colombia as a Teacher and Researcher in the line of environmental technology and materials, where they have developed a wide range of solids for water treatment. He has had the opportunity to learn and deepen in spectroscopic, texture and microscopic techniques for the characterization of materials. Also, in chromatographic techniques for monitoring the reactions evaluated.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

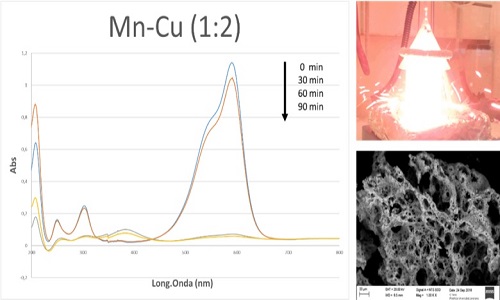

Currently the textile industry, educational centers and laboratories have a pollution problem due to the irresponsible discharge of dye wastewater into the waterways, which is generating a great impact on the quality and aesthetics of water resources. Recently, the use of mixed oxides has gained a great deal of interest in the advanced oxidation process (AOP) for the treatment of waste water of dyes due to its good degradation efficiency, low toxicity and physical and chemical properties. However, still using extreme conditions to remove contaminants, limits the use of these techniques for future industrial use. In this work the degradation of wastewater containing 50 mg/L violet crystal (VC) by air oxidation in a continuous flow trickle-bed reactor over CuxMnyMgAl catalyst obtained by auto combustion method were studied. It was found the decolorization efficiency and the chemical oxygen demand (COD) removal of VC reached above 92% and 100%, respectively, within 60 min at room temperature and atmospheric pressure. The total organic carbon (TOC) decreased 76.1%. The obtained samples were characterized by powder X-ray diffraction, fourier transform infrared, atomic absorption spectrometry, scanning electron microscope, N2 adsorption and temperature programmed reduction with H2. The results show that the activity on violet crystal oxidation was significantly influenced by the preparation method of the mixed oxides. The auto combustion method provides better catalysts because the redox properties improve and the specific area increase. The most effective catalyst was Cu2Mn1MgAl, with 100% of decolorization in 1 hour of the reaction. A real textile wastewater was also successfully treated with this catalyst. The monitoring by CG-MS allows recognizing the mineralization of the VC to CO2, H2O and compounds with shorter chains less toxic than the initial dye.

Debasish Biswas

Jadavpur University, India

Title: Observing giant room temperature magneto dielectric response in silica-based oxide nano glass

Time : 13:30-13:50

Biography:

Debasish Biswas has obtained his PhD in Experimental Physics at the University of Calcutta in 1999; Postdoctoral research work on ion trap spectroscopy in Penning trap. He has published in areas relating to spectroscopic study of atmospheric molecules and trace gases. Currently, he is a Professor in the Department of Physics at Jadavpur University, Kolkata, India and his primary role is of an Educator. His current research interest includes nanomaterials, space physics and atom optics.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

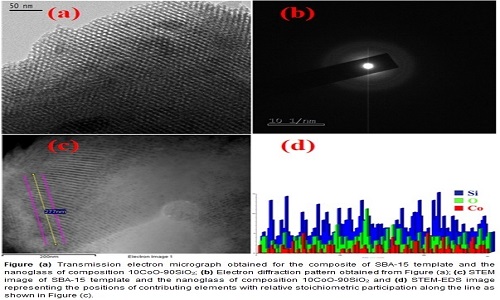

Nano dimensional silica-based glasses of compositions xCoO-(1-x)SiO2 with x having values 10 and 30 were synthesized by a sol-gel method within the nanopores of mesoporous template. X-ray photoelectron spectroscopic (XPS) analysis showed the presence of Co2+ and Co3+ species in the glasses causing electronic conduction in this amorphous system. At room temperature the resistivity values exhibited by the nano glasses were nearly three orders of magnitude lower than those of the corresponding bulk glasses. The resistivity data for the nano glasses on analysis confirmed the conduction to arise due to small polaron hopping between the localized states represented by those ions. Typical values of inter-site separation distance extracted from the said analysis were found to be ~7 Å. The values of magneto dielectric parameter for the different nanocomposites were large with the highest value found to be in the range 500% to 45% for the frequencies 1 kHz and 1 MHz respectively for a nanocomposite with glass composition of 30CoO-70SiO2. The results were then fitted to Catalon’s model based on two dielectrics in series with different resistivity values. The satisfactory fit of the measured data to the theoretical model based on a negative magneto resistance of the nano glasses indicate that an enhancement of spin polarized electron hopping caused this effect. The magnetization change as a function of the applied magnetic field was calculated for the nanocomposites. The super exchange interaction between Co2+ and Co3+ ions through the intervening oxygen ions gave rise to the ferromagnetic like behaviour of the samples. In future these materials may be used as good magnetic sensors.

Jean Francois Silvain

ICMCB-CNRS, France

Title: Thermal and thermomechanical properties of graphite flakes and carbon fibers reinforced aluminum matrix composites

Time : 13:50-14:10

Biography:

Jean-Francois Silvain is a Senior Researcher at ICMCB-CNRS and an Adjunct Professor of Engineering at UNL-Lincoln, USA. He has obtained his Bachelor’s degree at Poitiers University in 1980 and PhD degree at Poitiers University in 1984, both in Material Science. He was a CNRS Research Fellow at the University of Nancy, France from 1987 to 2002. He has joined the ICMCB-CNRS in 1992. He has over 30 years of experience in composite materials processing and characterization at micro/nano scales. His main field of interest is the processing and the characterization of ceramic and inorganic multi materials ranging from metal matrix composite to functionally graded materials with the aim to develop materials with adaptive physical and/or mechanical properties.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

Today, the microelectronics industry uses higher functioning frequencies in commercialized components. These frequencies result in higher functioning temperatures and, therefore, limit a component’s integrity and lifetime. Until now, heat-sink materials were composed of metals which exhibit high thermal conductivities (TC). However, these metals often induce large coefficient of thermal expansion (CTE) mismatches between the heat sink and the nonmetallic components of the device. Such differences in CTEs cause thermomechanical stresses at the interfaces and result in component failure after several on/off cycles. To overcome this issue, one solution is to replace the metallic heat sink materials by a metal matrix composites (MMCs), specifically, carbon-reinforced aluminum matrix (Al/C) which exhibit optimized thermomechanical properties. Moreover, due to his low density, 2.7 g/cm3, Al has a high specific thermal conductivity (TC divided by density) and low cost which are great advantages in terms of the fabrication of mobile electronic devices for automobile or aeronautic industries. Carbon fibers (CF) and graphite flakes (GF) were preferred to diamond particles because of their low coefficient of thermal expansion (CTE), high thermal conductivity (TC), and a good machinability. These reinforcements will allow developing composite materials that fulfill the requirements related to the field of power electronics. However, the anisotropic thermal properties of these reinforcements may generate a strong influence of the reinforcement orientation on the macroscopic thermal properties of the MMC. Moreover, the oxide layer on Al particles inhibits Al-C reactivity. Therefore, the areas of research discussed in this work are: Orientation optimization of anisotropic reinforcements by a microstructural design Development of composite materials with mixed reinforcement (GF+FC) to evaluate the influence of the combination of the two reinforcements on the thermomechanical properties; Elaboration of composite materials by liquid phase sintering in order to optimize the interfacial properties and densification of composite materials with high carbon content.

Debajyoti Ghoshal

Jadavpur University, India

Title: Transformation directed functionality in dynamic metal-organic framework based materials

Time : 14:10-14:30

Biography:

Debajyoti Ghoshal has completed his Doctoral studies at Indian Association for the Cultivation of Science, Kolkata and got his PhD at Jadavpur University, India in 2005. After that he has worked at the University of Gottingen, Germany as an Alexander von Humboldt fellow, to purse his Postdoctoral research. Currently, he is an Associate Professor in the Department of Chemistry at Jadavpur University and his current research interest includes functional metal organic frameworks (MOF) with a special emphasis to the selective gas storage, conducting MOF and phase transformation in dynamic MOF. He has published more than 75 papers in peer reviewed journals which has received 1780 citation with h index of 26.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

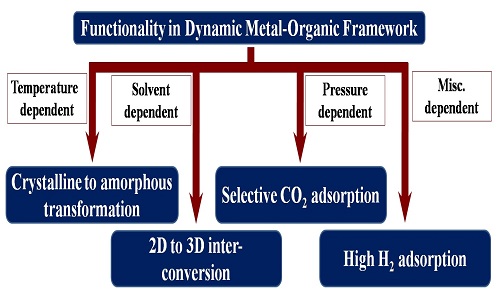

Dynamic metal organic frameworks (MOFs) have become a very promising field in contemporary research not only due to their study in understanding structural features but also for their potential applications in tailoring better functionality. The transformation of phase which is the fundamental thing of such structural dynamicity can be initiated by various external stimuli like heat, light, pressure, solvent etc. This dynamism in the structure of MOF based material can proceeds through physical as well as chemical changes. Interestingly, it has been noted that for such dynamic MOFs, the transformed phase may sometime display stepwise gas and/or solvent adsorption and also show selective gas adsorption. These functionalities in dynamic MOFs might be found pretty useful for gas and/or solvent separation. Moreover, as the change of phase are generally taken place by some external stimuli, monitoring of the change in the structures of dynamic MOF, can be used as a sensor for the responsive stimuli both as qualitative (molecular recognition and/or sensing) as well as quantitative (impurity measurement) way. In many of our recent work, it has been observed that in the study of flexible MOFs with their structural dynamicity most of them show reversible crystalline-to-crystalline transformation whereas in some cases rare reversible crystalline-to-amorphous transformation has also been observed. In every case, various external stimuli like heat, pressure, solvents etc, individually or cooperatively facilitate the transformations to another phase. There are several interesting properties have been observed for these transformed products. For example, one pair of MOFs show interesting solvent mediated inter-conversion from 2D to 3D framework and this change in dimension affects their adsorption properties too. In another endeavour, one pair of nitro functionalized MOFs exhibit selective CO2 adsorption after the transformation of phase. A polycatenated framework also shows a temperature as well as pressure mediated structural transformation; where the transformed phases are capable to show remarkable H2 uptake.

Tsan Yao Chen

National Tsing Hua University, Taiwan

Title: X-ray absorption spectroscopy and in-operando neutron diffraction studies on local structure fading induced irreversibility in a 18650 cell with P2-Na2/3Fe1/3Mn2/3O2 cathode in long cycle test

Time : 14:30-14:50

Biography:

Tsan Yao Chen is currently an Associate Professor at Department of Engineering and System Science, National Tsing Hua University. With more than 10 years of experience in Materials Characterization and 6 years in electronic device (MEMS and IC), failure analysis of multiple executives by Synchrotron Light Source Techniques (at NSRRC, Taiwan). He conduct fundamental materials development in green energy applications including solar cell, fuel cell, and CO2 conversion, water sensing with worldwide collaboration at National rank research team in Russia, USA, Italy, Japan (SPring-8), and UK. He is hosting research projects from academic and industrial funds on physical chemistry researches and environment sensing technologies.

To present & exhibit your MATERIALS @ our upcoming series PS: Materials Conferences | Materials Chemistry Conferences | Materials Chemistry 2020

Abstract:

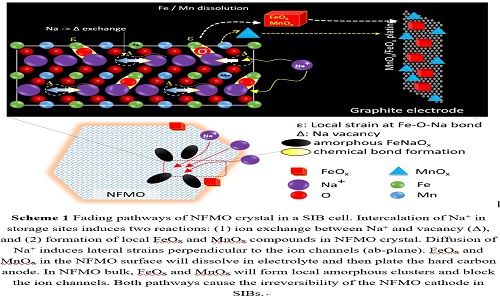

Cathode materials of P2-Na2/3[Fe1/3Mn2/3] O2 (NFMO) phase nanoparticle with a maximum capacity of ~148 mAh in a sodium ion battery was synthesized by a solid-state annealing method. By cross-referencing results of focused-ion beam (FIB) section scanning electron microscopy, ex-situ X-ray absorption spectroscopy (XAS), X-ray photoemission (XPS) depth profiling, and in-operando neutron diffraction, we found that Na ion intercalation and extraction distort the local structure in NFMO crystal, resulting in irreversibility of the sodium ion battery (SIB). This reaction pathway is controlled by the transformation kinetics of the Fe sites from octahedral (Oh) to tetragonal (Td) in the charge and discharge processes. For a SIB operated at 2.0 to 3.8V, steady kinetics between the Na intercalation and chemical state evolution on the Fe sites enable the homogeneous restructuring in both local and global regimes in NFMO crystal. For a SIB operated at 2.0 to 4.5V, substantially higher kinetics in the Fe chemical state evolution induces a dramatic lattice expansion. This expansion cracks the interface between the P2 and Na intercalated regions, thereby causing substantial irreversibility of NFMO in a SIB.