Jean Francois Silvain

ICMCB-CNRS, France

Title: Physical properties of metal-matrix composite materials

Biography

Biography: Jean Francois Silvain

Abstract

Both high thermal conductivities and low thermal expansion coefficients (CTE) are required for heat-sink materials as they promote rapid heat dissipation and tolerate thermo-mechanical strains upon thermal cycling. Currently, Cu or Al heat sinks are being used. However, they are not suitable due to the large CTE mismatch with the ceramic and silicon parts in the components. To overcome this issue, we proposed to replace the Cu and Al heat sinks by metal matrix composites (MMCs), more particularly Al and Cu matrix composites reinforced with carbon. The properties in MMCs is often compromised by the absence of effective interfaces, especially in non-reactive systems such as Al(Al2O3)/C and Cu/C. However, for a thermally efficient assembly, the interface should allow proper transfer of thermo-mechanical loads between the materials, which is only possible in the presence of chemical bonding. Ex-situ and in-situ methods can be used to form interfacial metal-matrix zones with optimized physical properties. An ex-situ method developed in this study is correlated with the synthesis of a hybrid TiOx/TiC coating on carbon fibers (CFs) using molten salt synthesis. The molten salt synthesis method is a facile and efficient way for the synthesis of transition metal carbides at low temperatures in a relatively short time. The in-situ method is linked with the synthesis of composite materials by alloying the matrix with carbide forming elements which has been investigated using a well-known process used for Al-based composites. The solid-liquid coexistence allows the formation of a liquid phase which enhances the reactivity between the carbide forming element and the carbon reinforcement. For both ex-situ and in-situ MMC composite materials, the fabrication conditions will be correlated with the microstructures of the interfacial zones and the physical properties of the MMC materials.

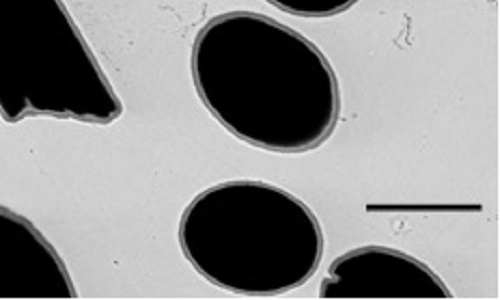

In situ formation of TiC interfacial zone between carbon fibers and copper matrix (bar equal 10 microns).